商铺名称:鑫洋塑胶原料贸易行

联系人:易小姐(小姐)

联系手机:

固定电话:

企业邮箱:335171600@qq.com

联系地址:杨先生:13650067339 常平镇大京九塑胶城塑通八路

邮编:523576

联系我时,请说是在新塑胶网上看到的,谢谢!

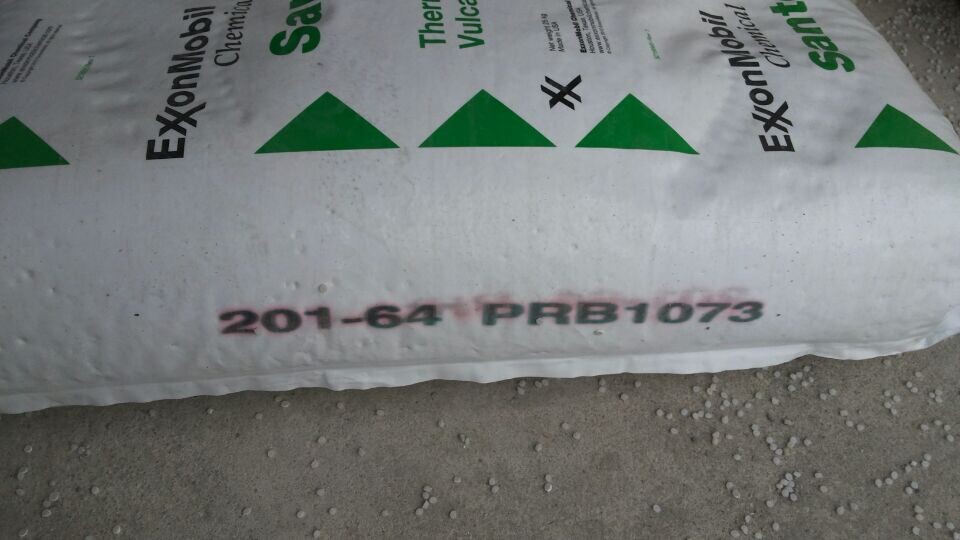

长期供应美国三都坪 TPV 101-60W261 价格合理,诚信经营,可全国供货(广东省内 免费送货上门)。

“十年老店,完备售后,信誉信赖” 是专业塑胶原料供应商

本司货源稳定充足,发货准时,交期和质量均有保障!

根据客户要求,可提供塑胶原料相关报告。如:ROHS(SGS)报告,UL认证,材质证明及物质安全资料表(MSDS)!

欢迎来电咨询7*24全天候服务热线:13686017791 易小姐 QQ:335171600

透明塑料制品注塑成型工艺

透明塑料由于透光率要高,必然要求塑料制品表面质量要求严格,不能有任何斑纹、气孔、泛白。雾晕、黑点、变色、光泽不佳等缺陷,因而在整个注塑过程对原料、设备。模具、甚至产品的设计,都要十分注意和提出严格甚至特殊的要求。其次由于透明塑料多为熔点高、流动性差,因此为保证产品的表面质量,往往要在机高温度、注射压力、注射速度等工艺参数作细微调整,使注塑料时既能充满模,又不会产生内应力而引起产品变形和开裂。因此从原料准备,对设备和模具要求、注塑工艺和产品的原料处理几方面都要进行严格的操作。

一、料的准备与干燥由于在塑料中含有任何一点杂质,都可能影响产品的透明度,因此和储存、运输。加料过程中,必须注意密封,保证原料干净。特别是原料中含有水分,加热后会引起原料变质,所以一定要干燥,并在注塑时,加料必须使用干燥料斗。还要注意一点的是干燥过程中,输入的空气最好应经过滤、除湿,以便保证不会污染原料。其干燥工艺如,透明塑料的干燥工艺:材料工艺干燥温度(℃)干燥时间(h)料层厚度(mm)备注pmma70~802~430~40pc120~130>6<30采用热风循环干燥pet140~1803~4采用连续干燥加料装置为佳

二、机筒、螺杆及其附件的清洁为防止原料污染和在螺杆及附件凹陷处存有旧料或杂质,特别热稳定性差的树脂存在,因此在使用前、停机后都应用螺杆清洗剂清洗干净各件,使其不得粘有杂质,当没有螺杆清洗剂时,可用pe、ps等树脂清洗螺杆。当临时停机时,为防止原料在高温下停留时间长,引起解降,应将干燥机和机筒温度降低,如pc、pmma等机筒温度都要降至160℃以下。(料斗温度对于pc应降至100℃以下)

三、在模具设计上应注意的问题(包括产品的设计)为了防止出现回流动不畅,或冷却不均造成塑料成型不良,产生表面缺陷和变质,一般在模具设计时,应注意以下几点。a=壁厚应尽量均匀一致,脱模斜度要足够大;b=过渡部分应逐步。圆滑过渡,防止有尖角。锐边产生,特别是pc产品一定不要有缺口;c=浇口。流道尽可能宽大、粗短,且应根据收缩冷凝过程设置浇口位置,必要时应加冷料井;d=模具表面应光洁,粗糙度低(最好低于0.8);e=排气孔。槽必须足够,以及时排出空气和熔体中的气体;f=除pet外,壁厚不要太薄,一般不得小于lmm。

部分型号部分物性表

Physical Properties

Metric

English

Comments

Specific Gravity

0.980 g/cc

0.980 g/cc

23°C; ASTM D792

Mechanical Properties

Metric

English

Comments

Hardness, Shore A

48

48

0.078 in; ASTM D2240

Tensile Strength at Break

4.00 MPa

580 psi

Across Flow; ASTM D412

Tensile Stress

1.40 MPa

@Strain 100 %

203 psi

@Strain 100 %

Across Flow; ASTM D412

Elongation at Break

400 %

400 %

Across Flow; ASTM D412

Thermal Properties

Metric

English

Comments

Flammability, UL94

HB

@Thickness 1.70 mm

HB

@Thickness 0.0669 in

HB

@Thickness 3.00 mm

HB

@Thickness 0.118 in

Descriptive Properties

Change in Mass in IRM 903 Oil at 257°F for 70 hr

0.35

Color

Black

Form

Pellets

LDPE (low density polyethylene # LDPE) /CP plastic 763F-01/ Schulman

Uses: other

Characteristic note: good heat sealing and processability

Important parameters: melt flow rate: 1 g/10min density: 0.918 g/cm3 tensile strength: 10 MPa elongation at break: 200% bending modulus: 207 MPa hardness: 42 VEKA softening point: 92 DEG C

Manufacturer: Schulman plastics

LDPE (low density polyethylene LDPE #) /DND2450/ Japan Younika

Uses: other

Features: hollow blow molding, good formability, good drug resistance, good transparency, good flexibility and good gloss

Important parameter: melt flow rate: 1.3 g/10min density: 0.92 g/cm3

Manufacturer: KK, Japan Ltd.

LDPE (low density polyethylene LDPE /F404-H/ Japan Sumitomo #)

Application: film grade

Characteristic feature: impact strength and smoothness is very good, the film thickness of 12.5-40 microns

Important parameter: melt flow rate: 3.5 g/10min density: 0.92 g/cm3

Manufacturer: Sumitomo Chemical Industries Ltd

LDPE (low density polyethylene LDPE #) /CA8200/ Borealis

Uses: other

Features: moisture resistance, recyclable materials, good heat sealing, good cohesiveness, low odor, no additives

Important parameter: melt flow rate: 7.5 g/10min density: 0.918 g/cm3

Manufacturer: Nordic Chemical Company Limited

LDPE (low density polyethylene # high-pressure polyethylene) /N150/ Shanghai petrochemical

Application: film grade

Characteristic note: polymer type: homopolymerization

Important parameters: melt flow rate: 1.5 g/10min density: 0.918 g/cm3 tensile strength: 12.5 MPa, elongation at break: 550%

Manufacturer: Sinopec, Shanghai petrochemical, Limited by Share Ltd

LDPE (low density polyethylene # LDPE) /2602TH33/ SABIC of Saudi Arabia

Application: film grade

Characteristic note: high optical performance and low coefficient of friction. Product trademark: SABIC

Important parameters: melt flow rate: 2.5 g/10min density: 0.926 g/cm3 notched impact strength: 20 tensile strength: 20 MPa, elongation at break: 500%

Saudi Basic Industries, Inc.

LDPE (low density polyethylene # high-pressure polyethylene) /LDF-250YZ/ Malaysia daito

Application: film grade

Characteristics: good mechanical properties and hardness

Important parameters: melt flow rate: 0.75 g/10min density: 0.922 g/cm3 notched impact strength: 4 tensile strength: 23 MPa, elongation at break: 560% VEKA softening point: 93 DEG C

Manufacturer: Malaysia daito company

LDPE (low density polyethylene # high-pressure polyethylene) /LDF-266YZ/ Malaysia daito

Application: film grade

Characteristics: good machinability and mechanical properties

Important parameters: melt flow rate: 0.25 g/10min density: 0.922 g/cm3 notched impact strength: 4 tensile strength: 19 MPa, elongation at break: 570% VEKA softening point: 100 DEG C

Manufacturer: Malaysia daito company

LDPE (low density polyethylene # LDPE) /PE-046/A/ Repsol of Spain

Application: film grade

Characteristic note: good machining, high definition

Important parameters: melt flow rate: 2 g/10min density: 0.92 g/cm3, elongation at break: 650% VEKA softening point: 90 DEG C

Manufacturer: YPF of Spain

LDPE (low density polyethylene # LDPE) /PE-063/A/ Repsol of Spain

Uses: other

Remark: food contact is acceptable and well processed

Important parameters: melt flow rate: 4 g/10min density: 0.92 g/cm3, elongation at break: 600% VEKA softening point: 88 DEG C

Manufacturer: YPF of Spain

LDPE (low density polyethylene # high-pressure polyethylene) /NA985107/ quantum chemistry

Uses: other

Features: copolymer, food, contact, acceptance, heat sealing, high impact resistance, film

Important parameters: melt flow rate: 0.25 g/10min density: 0.921 g/cm3 tensile strength: 19.3 MPa elongation at break: 500% VEKA softening point: 91 DEG C

Manufacturer: quantum chemical company of America

LDPE (low density polyethylene LDPE #) /3026HK/ Leander Basel

Application: film grade

Characteristic note: low friction, good processability and good rigidity

Important parameters: melt flow rate: 2 g/10min density: 0.927 g/cm3 tensile strength: 13 MPa elongation at break: 650% hardness: 51 VEKA softening point: 100 DEG C

Manufacturer: Basel industries, Inc.

LDPE (low density polyethylene LDPE #) /2420H-TP/ Leander Basel

Application: film grade

Important parameters: melt flow rate: 2 g/10min density: 0.924 g/cm3 tensile strength: 12 MPa hardness: 48 VEKA softening point: 94 DEG C

Manufacturer: Basel industries, Inc.

LDPE (low density polyethylene # LDPE) /PE-033/ Repsol of Spain

Uses: other

Features: antioxidants, food contact, acceptable, good processing

Important parameters: melt flow rate: 0.3 g/10min density: 0.922 g/cm3, elongation at break: 650% VEKA softening point: 94 DEG C

Manufacturer: YPF of Spain

LDPE (low density polyethylene # high-pressure polyethylene) /2426K/ Lanzhou petrochemical

Uses: film grade stretch stretch film, film grade - packaging film

Important parameters: melt flow rate: 3.7 g/10min density: 0.925 g/cm3 tensile strength: 9.9 MPa, elongation at break: 540%

Manufacturer: PetroChina Lanzhou Petrochemical Branch Company

LDPE (low density polyethylene LDPE #) /LD-01A/ Korea Dalin

Application: film grade

Characteristics: excellent impact resistance, excellent heat sealing property, excellent mechanical properties and processability.

Important parameters: melt flow rate: 0.25 g/10min density: 0.922 g/cm3 notched impact strength: 700 tensile strength: 21 MPa, elongation at break: 480%

Manufacturer: Korea Dalin Co.

LDPE (low density polyethylene # high-pressure polyethylene)